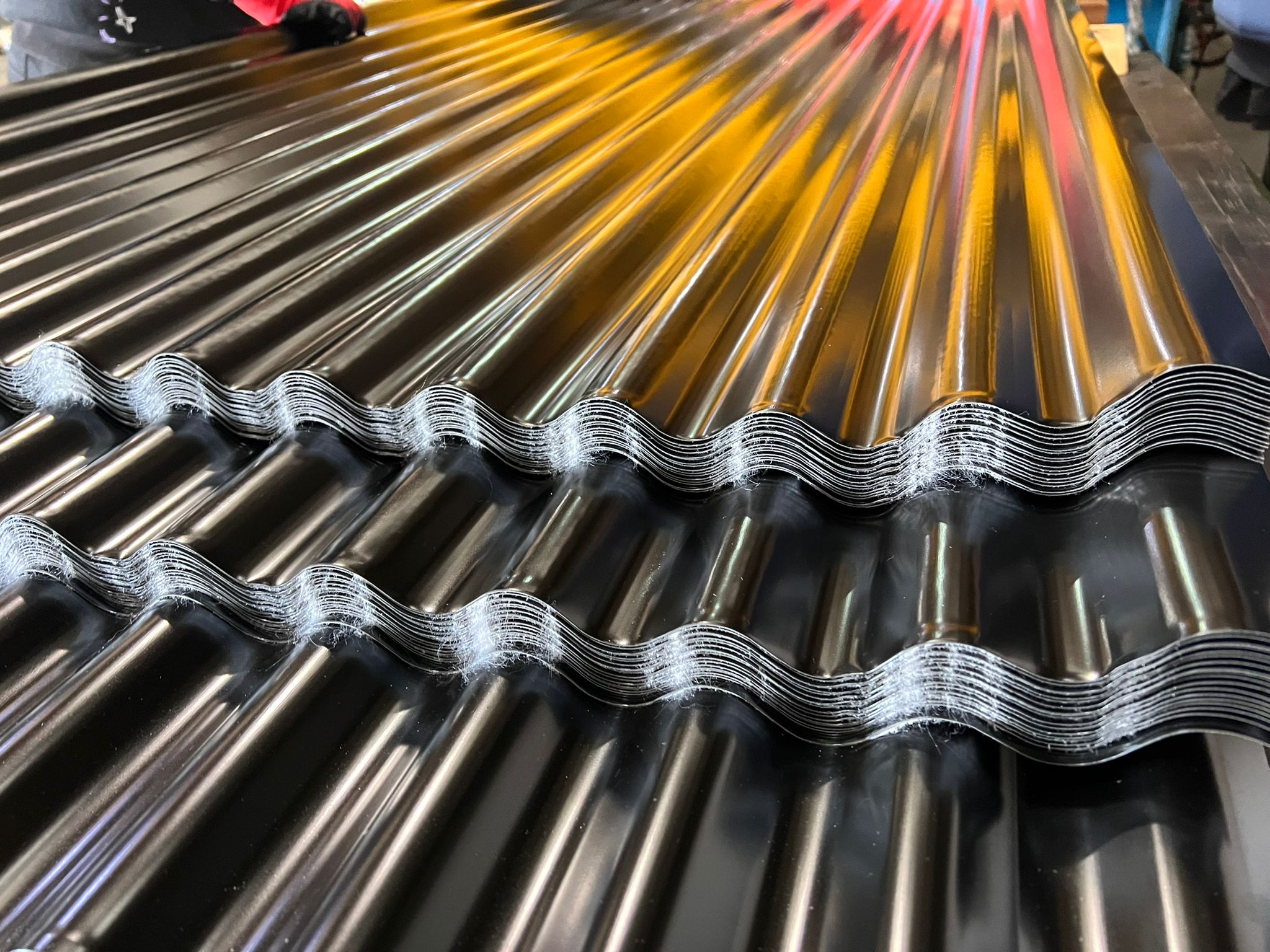

Metal roofing sheets are known for their durability and long service life, but like any material, they don’t last forever. Over time, weather, wear and poor maintenance can take their toll. Spotting early signs of damage or deterioration is essential, not just to avoid leaks but to protect the underlying structure of your building.

Whether you’re maintaining a garage, workshop or industrial unit, knowing what to look for can help you plan timely repairs or replacement. In this guide, we’ll highlight 12 of the most common tell-tale signs that your roofing sheets might need replacing – and what to do when you notice them.

1. Leaks or Drips After Rainfall

Perhaps the most obvious sign something isn’t right. If you notice water making its way into the space beneath your roof after rain, your roofing sheets may be compromised. Leaks can result from rust, failed seals at overlaps or cracks in the sheet itself. While minor leaks can be patched, widespread water ingress often points to the need for full replacement.

2. Rust and Corrosion

Modern roofing sheets are coated to resist rust, but over time this protective layer will wear away. This is usually caused by the age of physical damage, after which corrosion will quickly spread and compromise your roof sheets. Small rust spots may be treatable with rust converters and protective paints, but if the sheets are heavily pitted or flaking, this can be a clear sign that full replacement is required.

3. Warping or Buckling

Metal sheets that are bent, warped or lifting at the edges no longer provide a secure seal, as this compromises the tight overlap joints that are essential for weatherproofing. This often happens with age, poor installation or after heavy storms. Warped sheets can allow water and debris underneath the roofing structure, increasing the risk of leaks and rot. If you notice uneven panels, replacement may be more cost-effective than continual patching.

4. Loose or Missing Fixings

Fixings are what hold your sheets in place. If they’re missing, rusted through or no longer sitting flush, the entire panel can become unstable. When fixings don’t sit flush, they create raised points that can catch wind and put additional stress on surrounding fasteners, potentially creating a cascade of failures across the roof.

A few missing screws might be a simple fix – but if the sheet has started to shift or rattle in the wind, it could be a symptom of deeper issues requiring full sheet replacement. Wind rattling is particularly concerning because it indicates the sheet is already moving beyond its designed tolerances, which puts enormous strain on the remaining fixings.

5. Excessive Condensation or Damp Inside

Metal roofs are typically good at managing moisture. But if you start seeing damp patches on the ceiling or insulation, it may be a sign that the roof’s barrier has failed. These damp areas often appear gradually and may initially be mistaken for minor condensation issues.

This can be due to poor ventilation, but it’s often made worse by worn or thin sheets that no longer insulate or seal effectively. As metal sheets age and thin out, they lose their ability to maintain consistent temperatures, leading to increased condensation formation on the underside. When combined with compromised seals or micro-perforations from corrosion, even small amounts of moisture can accumulate and eventually work their way through to your ceiling spaces.

6. Discolouration or Fading

While this might seem like a cosmetic concern rather than a structural one, severe fading or uneven discolouration can point to UV damage or degradation of the protective coating your roofing sheets possess. It’s important to keep an eye on this, as once this coating is compromised, sheets are more vulnerable to rust, leaks and cracking. If multiple sheets show signs of wear, replacing them before corrosion sets in can save money long term.

7. Cracking or Splitting at the Edges

Sheet edges are particularly exposed to wind and rain, especially at overlaps and eaves. If you notice cracks, splits or fraying, the integrity of the entire panel is at risk. These cracks often grow over time, letting water in and allowing rust to take hold.

8. Noise During Windy Weather

Like we mentioned previously, persistent rattling or banging noises during light to strong winds suggest that your roofing sheets are no longer securely fixed in place. A bit of creaking is normal, especially during stronger winds, but it’s the more significant noise during windy weather you should be aware of.

This could be attributed to warped sheets, failed roof fixings or deteriorating underlays beneath the roof structure. If noise increases over time, it’s worth investigating further, as replacing your metal roofing sheets may be safer and quieter in the long run.

9. Signs of Mould or Moss Growth

Mould and moss can often grow on roofing sheets, especially in shaded or damp areas such as under overhanging trees, near gutters or in valleys where water tends to pool and debris accumulates. While some growth is superficial, heavy moss or algae can trap moisture against the sheet surface. Over time, this encourages corrosion, particularly where water sits along overlaps or fixings. Sheets showing repeated regrowth or water staining should therefore be inspected for replacement.

10. Poor Energy Efficiency

If your building is noticeably colder in winter or hotter in summer than it used to be, it might not just be the insulation. Worn or thinning sheets can lose their reflective or insulating qualities, especially if the underside is damaged or if there are air gaps. By replacing ageing sheets, you can help restore your roof structure’s thermal performance and potentially reduce energy costs.

11. Repeated Repairs

it might seem obvious, but if you have roofing sheets which are constantly requiring maintenance and upkeep, it’s probably worth replacing them altogether just to be safe. While one or two repairs are manageable, constantly patching leaks, resealing overlaps or replacing fixings, points to the fact that those roof sheets could be in need of replacement. Over time, piecemeal repairs become less effective and more costly compared to simply installing new sheets that are built to last.

12. Sheets Are Past Their Expected Lifespan

Finally, don’t underestimate the value of a calendar. Even well-maintained sheets have a finite lifespan. Galvanised steel sheets typically last 15 – 25 years, while plastisol-coated options can last up to 30. If your roof is approaching or beyond that age range, replacement may not be urgent, but it should definitely be on the radar.

Final Thoughts

Not every issue with your roof means immediate replacement – but ignoring the warning signs can lead to much bigger problems down the line. If you spot any of the signs above, it’s worth having the roof inspected by a professional. A timely replacement can save money on repairs, improve energy efficiency and offer peace of mind for years to come.

If you’re unsure whether your sheets need replacing or you’d like guidance on choosing the right product for your project, get in touch with our team at Cardinal Steels. We’re always happy to help with practical, no-nonsense advice.

FAQs

1. Can I replace just one or two roofing sheets?

If the damage is localised, replacing a few specific roofing sheets is acceptable. But if the surrounding sheets are also aged or showing signs of wear, a full replacement may be more cost-effective.

2. Is discolouration purely cosmetic, or does it affect performance?

Discolouration often signals UV damage to the coating, which can reduce the sheet’s resistance to rust and corrosion.

3. How long do steel roofing sheets typically last?

Galvanised sheets last 15 – 25 years on average, while plastisol-coated ones can last 25 – 30 years with proper care.

4. What’s the most common cause of roof sheet failure?

Weather exposure, especially rain, wind and UV, is the main factor. Poor installation and lack of maintenance can also accelerate wear.

5. Do I need planning permission to replace roofing sheets?

In most cases, no – especially if you’re simply replacing like for like. However, always check with your local authority if in doubt.