Structural integrity is of paramount importance in roofing systems as it directly affects the safety, durability, and functionality of a building. The roof serves as the first line of defence against environmental elements, such as heavy rain, high winds, and snow loads. A structurally sound roof ensures that the overall structure remains stable and protected, preventing water leakage, structural damage, and potential risks to occupants. Steel roofing sheets play a crucial role in upholding the structural integrity of the roof. With their inherent strength and durability, steel sheets provide robust support and load-bearing capacity, distributing the weight evenly across the structure.

They are designed to withstand various environmental stressors and maintain their shape and integrity over time, providing long-lasting protection for the building. By choosing the right steel roofing sheets and ensuring their proper installation, builders and homeowners can ensure a strong and stable roofing system that contributes to the overall structural integrity of the entire building.

Understanding Load Requirements

Roofing systems are subject to various types of loads that can exert forces on the structure. Understanding these loads and their impact on the design and selection of steel roofing sheets is crucial.

Dead Loads

Dead loads refer to the static weight of the roofing materials, supporting structures, and any permanent fixtures or equipment on the roof. These include the weight of the steel roofing sheets, insulation, decking, and other components. Dead loads are constant and do not change over time unless modifications are made to the roof. Proper consideration of dead loads is essential for determining the structural requirements and ensuring that the steel roofing sheets can support the weight without compromising the stability of the overall structure.

Live Loads

Live loads are dynamic loads that result from the occupancy of the building or temporary equipment placed on the roof. They include the weight of people, equipment, and movable objects that may be present on the roof at various times. Examples of live loads include maintenance personnel or rooftop installations. Steel roofing sheets must be designed to accommodate these live loads to prevent excessive deflection or structural failure.

Wind Loads

Wind loads are lateral forces caused by wind pressure acting on the roof surface. The magnitude of wind loads depends on factors such as the building’s location, height, exposure, and local wind speed criteria. Steel roofing sheets must be selected and installed considering the wind resistance requirements to withstand the expected wind pressures. This may involve choosing appropriate sheet profiles, fastening methods, and edge detailing to ensure the sheets can resist uplift forces and remain securely in place during high winds.

Snow Loads

Snow loads are applicable in regions where snowfall occurs. The weight of accumulated snow on the roof exerts significant downward force. The design and selection of steel roofing sheets should consider the expected snow loads based on local climate data. Adequate structural support and appropriate sheet thickness must be determined to withstand the weight of snow and prevent roof collapse.

Evaluating Steel Roofing Sheet Strength

The strength of steel roofing sheets is influenced by several factors that directly impact their performance and durability.

Material Thickness

The thickness of steel roofing sheets is a critical factor in determining their strength. Thicker sheets generally offer higher load-bearing capacity and structural integrity. Thicker gauges are often preferred in areas prone to severe weather conditions or where increased strength is required.

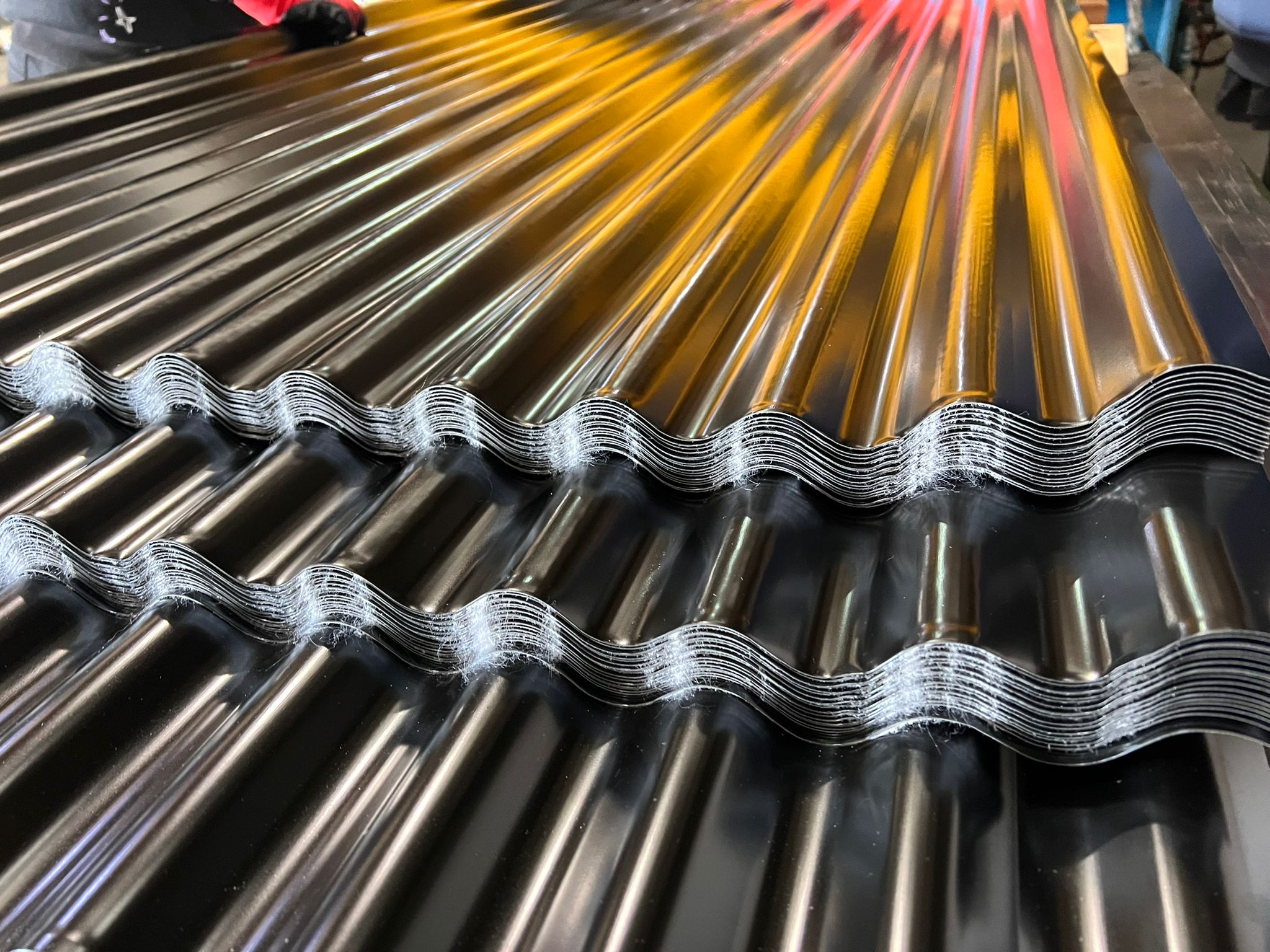

Material Grade

Steel roofing sheets come in different grades, such as galvanised steel coated with a layer of zinc. These grades determine the quality and protective coating applied to the steel. Higher-grade materials offer enhanced corrosion resistance, durability, and longevity, contributing to the overall strength of the roofing sheets.

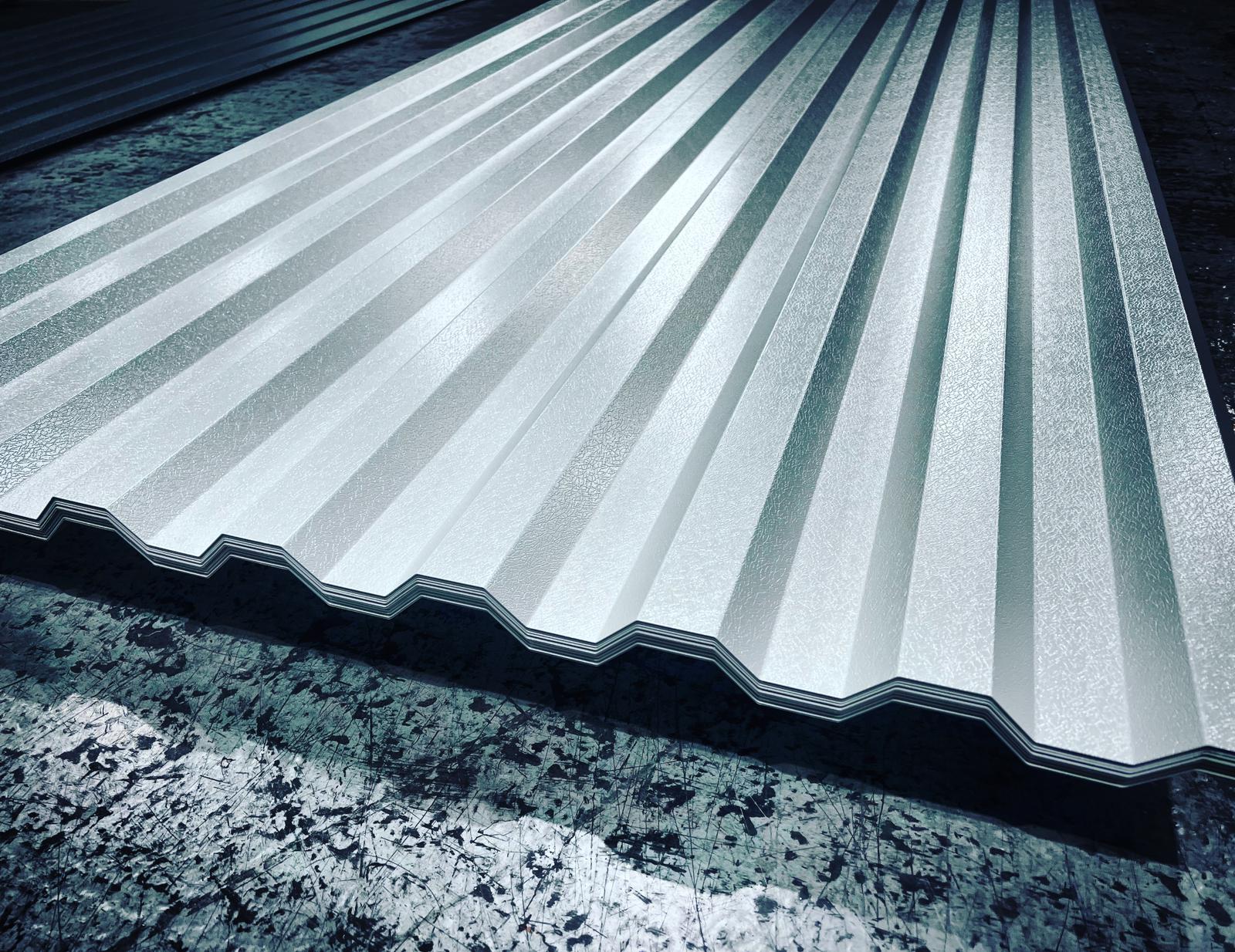

Sheet Profile

The profile or shape of the steel roofing sheets also affects their strength. Different profiles, such as standing seam, corrugated roofing sheets, box profile roofing sheets, or ribbed, provide varying levels of structural stability and load-bearing capacity. The profile design influences the sheet’s ability to distribute loads, resist wind uplift, and provide structural support.

Considerations for Building Type and Design

The specific type of building or structure plays a significant role in determining the appropriate selection of steel roofing sheets.

Residential Buildings

Residential buildings typically require steel roofing sheets that offer a balance of aesthetic appeal, durability, and cost-effectiveness. Considerations for residential buildings include the architectural style, slope of the roof, and homeowner preferences. Steel roofing sheets with a variety of profiles, colours, and finishes are available to complement different residential designs while providing the required strength and protection against the elements.

Commercial Structures

Commercial buildings often have larger roof areas and complex architectural designs. Steel roofing sheets for commercial structures should be chosen based on factors like load-bearing capacity, durability, and long-term maintenance requirements. Considerations may include accommodating rooftop equipment, drainage systems, and the ability to handle foot traffic for maintenance purposes.

Industrial Facilities

Industrial facilities, such as warehouses, factories, and manufacturing plants, require steel roofing sheets that can withstand heavy loads, harsh environments, and potential chemical exposure. Considerations include resistance to corrosion, impact resistance, and fire resistance. Industrial buildings may also require specific profiles, such as corrugated roofing sheets, to provide additional strength and rigidity.

Specialised Applications

Specialised applications, such as agricultural structures, sports facilities, or educational institutions, have unique requirements. Agricultural buildings may need steel roofing sheets with high resistance to corrosion from animal waste or agricultural chemicals. Sports facilities might require steel roofing sheets with exceptional sound insulation or specific profiles to accommodate lighting systems. Educational institutions may have architectural considerations such as skylights or solar panel integration.

By considering the specific requirements and design considerations for different building types, roofers can select the most suitable steel roofing sheets to ensure optimal performance, durability, and structural integrity for each application.

Consulting with experts Cardinal Steels

By involving experts, roofers can ensure that the roofing system is designed to withstand the expected loads, preventing structural failures or performance issues. Cardinal Steels can provide recommendations for the appropriate steel roofing sheets. Considering factors like material thickness, grade, profile, and coating options to ensure the selected sheets meet the necessary strength, durability, and performance criteria. By working closely with structural engineers, roofers can achieve a safe and durable steel roofing solution that meets structural requirements and delivers long-lasting performance.

Cardinal Steels manufactures and supplies a variety of steel roofing sheets and metal roof cladding. Our range includes box profile roofing sheets, corrugated roofing sheets, flat metal sheets, and insulated roofing. We offer competitive prices and nationwide delivery. All products are custom-made on-site to your specifications. Our steel roofing materials come with a 30-year guarantee. We serve industrial, commercial, residential, and agricultural sectors, providing solutions for garages, garden rooms, workshops, barns, factories, and more. Our friendly team of staff is readily available to provide expert advice on our products, contact us today.